Our machine technology can make things happen

THE STEPS OF MECHANICAL PRODUCTION AT WEFO

Thanks to continuous expansion and improvement of our machinery, we are state-of-the-art. At Wefo, we invest in innovation so that the demands of our clients will also be met in the future.

Manufacturing Areas

CNC Turning

Large quantities at consistent quality

CNC turning at Wefo

Our highlights of CNC turning technology:

- 2 machines

- Turned parts up to 728mm in length and 268mm in diameter

- 12-fold turret changer with radially and axially driven tools

CNC Milling

Absolutely precise workpieces up to 2600 mm

CNC milling technology of the latest generation at Wefo

Our highlights of CNC milling technology:

- 10 stations in total

- Strokes up to 2600x1100x900 mm

- State-of-the-art 5-axis technology

- DMF 260 with 60 tool changer places and internal tool cooling with 80 bar pump pressure and rotary table with a diameter of 1050 mm

- High-precision manufacturing

- Shortest processing times

Surface Grinding

We make it flat

Surface grinding at Wefo for precision components

Our highlights of surface grinding technology:

- Maximum clamping area of 1600x450x600 mm

- Maximum table load of up to 1200 kg

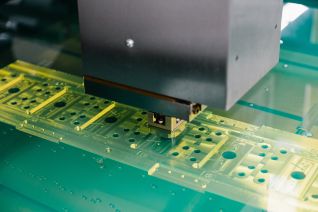

Die Sinking (EDM)

Explore the depth of the material

Die Sinking at Wefo for complex surfaces

Our highlights of die sinking technology:

- Maximum stroke 1000x1510x700 mm plus C-axis

- Maximum table load of up to 7500 kg

- Electrode holder with Erowa quick changer

Deep hole drilling

Precise, deep drilling to complete our scope of supply

Wefo´s deep hole drilling

Our highlights of deep hole drilling technology:

- Maximum strokes of 1300x600x1000 mm

- Maximum spindle rotations 4000 rpm

- Table load up to 5000 kg

- Table adjustment of 360°